Mounting the panelsWhichever panel type you choose, they must be mounted on the roof of the vehicle. Choose an area where there is no shadowing from other roof mounted items. In the case of the MC panels, even the shadow of an antenna like a CB whip can be detected as a power loss. A shadow area the size of your hand may reduce the output by 20%.

Panels work best when the flat surface is 90 degrees to the sun. Imagine a one foot square “beam” of sunlight. That one square foot will intercept the panel with the smallest area footprint when the beam is 90 degrees to the panels surface. If the panel is flat and the “sunbeam” is coming at a 45 degree angle, that one square foot of ”sunbeam” covers a much larger area, which means much reduced energy being captured by the panel.

Many folks have their panels mounted so that they can be tilted to the best angle for their l attitude and time of year. Some even have them mounted so they can be rotated to follow the sun. However, in practice, if you keep the panels within 20 degrees of the “sunbeam”, you will achieve about 90% efficiency.

Although I have mine mounted so I can tilt then, I opted to add more panels to offset the inefficiency induced by their being flat. I don't like to climb up on the roof and I don't have to worry about damage from the surprise 60+ mile per hour winds that happen in the desert. This works fine for me during all but the deepest winter days. Then the sun is at such a low angle that I sometimes do not have enough panel area to fully recharge my batteries. For that reason and some others, I carry a small 2kw generator (which I seldom use).

It is difficult to explain mounting methods due to the large variables in roof conditions. Some friends have built a grid like framework and attached the panels to the grid. I put mounting brackets in each corner and glued/screwed the brackets to the roof. My roof is rubber coated so I had to be sure that I used compatible adhesives.

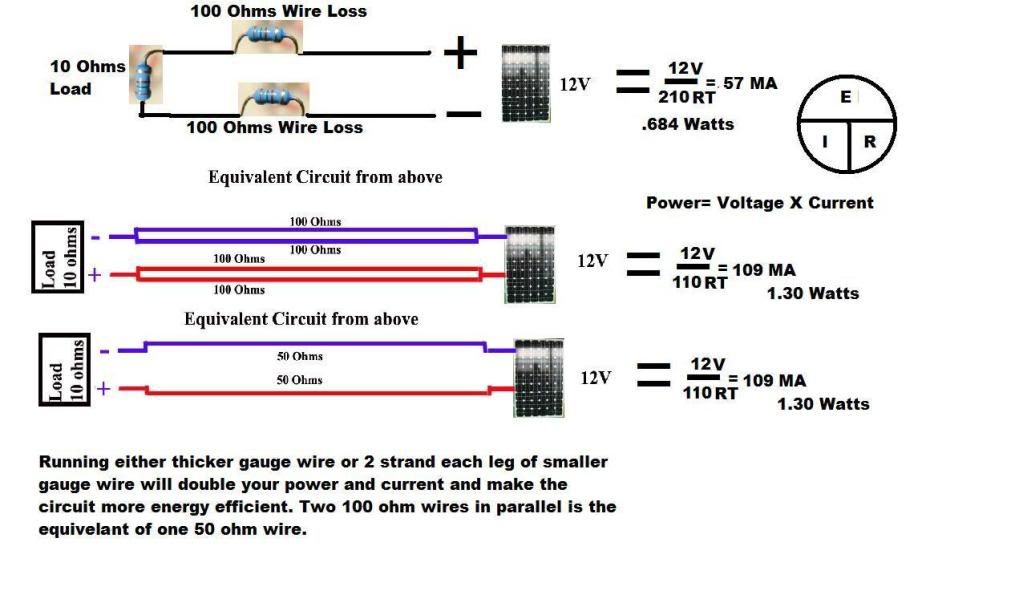

Wire:This is probably the most overlooked component of most solar systems. Many professional installers will use wire that has much smaller current carrying capacity than needed. Voltage drop between the panels and the controller can result in wasting a good portion of your collected energy. It is best to keep the voltage drop below 5%, but 3% would be much better.

Here is a table showing how wire size affects current flow. This chart uses the formula;

Voltage Drop = Current x Length x Ohms per Foot.

Where:

- Voltage Drop is the reduction of voltage at the load end of the circuit measured in volts. If the input voltage is 12 volts and the voltage drop is 4.2 then the voltage at the end of the wire pair is 12-4.2 or 7,8 volts.

- Current is in amps.

- Length is length of a single wire, The calculations below double that number for the total round trip wire length.

- Ohms per foot is the resistance per foot.

Data is from a standards table.

The table assumes 12 Volts, 15 Amps & 35 feet of cable. The cable length is doubled in the calculation.

Wire

Gauge | Ohms

Per 100' | Voltage

% Drop | Voltage

Drop | Volts

@End | Watts

Delivered | Watts

Lost | . |

16 | 4.02 | 4.22 | 35.14 | 7.78 | 116.75 | 63.25 | Note 1 |

| 12 | 1.59 | 1.67 | 13.9 | 10.33 | 154.99 | 25.01 | - |

| 10 | 1.00 | 1.05 | 8.74 | 10.95 | 164.27 | 15.73 | - |

| 8 | 0.63 | 0.66 | 5.5 | 11.34 | 170.11 | 9.89 | Note 2 |

| 6 | 0.4 | 0.41 | 3.46 | 11.59 | 173.78 | 6.22 | Note 3 |

| 4 | 0.25 | 0.26 | 2.17 | 11.74 | 176.09 | 3.91 | - |

| 2 | 0.16 | 0.16 | 1.37 | 11.84 | 177.54 | 2.46 | - |

Note 1: Here the wire size is 16 gauge. I have seen #16 used in some professional installations. They ran the wire to the refrigerator feed circuit and then tapped off of that at the controller. Needless to say it did not work very well. The owner was told he needed more panels. In my typical 35 foot run only 7.78 volts are making it to the battery.

Note 2: Here 8 gauge wire is used. Note the % drop is now 5.5% with an end voltage of 11.34. This is usable but we are still loosing .66 volts.

Note 3: Now 6 gauge wire. Voltage drop is 3.46% with a resulting end voltage of 11.59. OK we can live with that.

I use #10 wire on the roof to connect each panel individually to a common point, From there I have #4 wire to the controller. Overkill? Well perhaps, but my losses are very small.

It is important to note that the wire should be stranded, not solid. Although solid wire does give better performance with DC, it is much more prone to break from vibration.

All terminals should be either positive screw type or crimped terminals. Do not use soldered connections. Two reasons.

One, a soldered connection puts all the vibration stress at the same point, right at the end of the solder mass. Vibration on the wire will cause a great deal of stress here and the potential for a break is high. Soldered connections are no longer allowed in aircraft and most military applications.

Crimps put the forces at random places on each strand. Although a strand may break, the applied forces will not be focused at the exact same spot and the cable will have a significantly greater mean time between failure.

Second, the wire must have an ultraviolet and abrasion resistant jacket. On our first camper, I used white “marine” grade wire and the jacket began to show signs of failure within two years. I don't know why Anchor Marine Grade wire is not UV proof, but it seems not to be. UV proof wire is black. So is direct burial wire, however some direct burial jacketing is not UV proof. Stands to reason, it is for underground use. No UV there.

Be sure to leave enough wire to allow for raising the panels. I put a bit extra so I can move the panels around if necessary when working on the roof. I dislike breaking the connections because I use “liquid electrical tape” to coat all the connections. I have used this underneath a vehicle exposed to Maine winters and after 5 years the connections were like new.

If wire must be run at right angles to the air flow and it is not securely fastened to the roof, (ie: a piece running between two supports several inches above the roof), put several twists in the wire. If it is flat, it will vibrate and quickly fail.

Running the wire through the roof is always scary. Many folks run it in through the refrigerator vent. If you do this, be aware of the heat generated by the refrigerator. Either shield the wire from the heat or run it as far away from the head convection path as possible.

It is far better to cut a hole in the roof, mount an acceptable waterproof connection box and seal the whole mess with suitable caulking. Remember that the rubber roofing now being supplied with most RV's does not like silicone based adhesives. Use the proper stuff like Dicor or equivalent.

Mine is run through the refrigerator vent. But only for a very short length and it is shielded from the heat. I run each panels cable to a common block just inside the camper on the interior wall near where the refrigerator vent goes. All connections are inside and provide easy access.

The panels can be wired in either parallel or serial configurations. Parallel wiring gives the same voltage but with increased amperage. Serial configurations give a higher voltage but with lower amperage. Both provide the same amount of energy. The advantage of the serial arrangement is that the wire can be smaller. But it produces either 24 or 48 volts. This is usually done only with systems that generate large amounts of power. Remember the wire size chart? Well careful investigation will disclose that for large amounts of current, large wire sizes are needed. Increase the voltage and the current drops so much smaller wire can be used. I have several friends with large solar arrays that use 24vdc serial systems. Otherwise the wires would be too thick to easily manage.

OK, we have the panels installed and wired. Next comess the Solar Controller

===================

Nomad